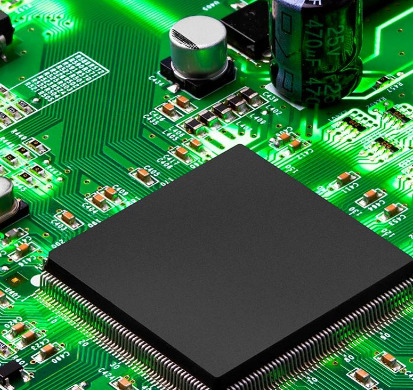

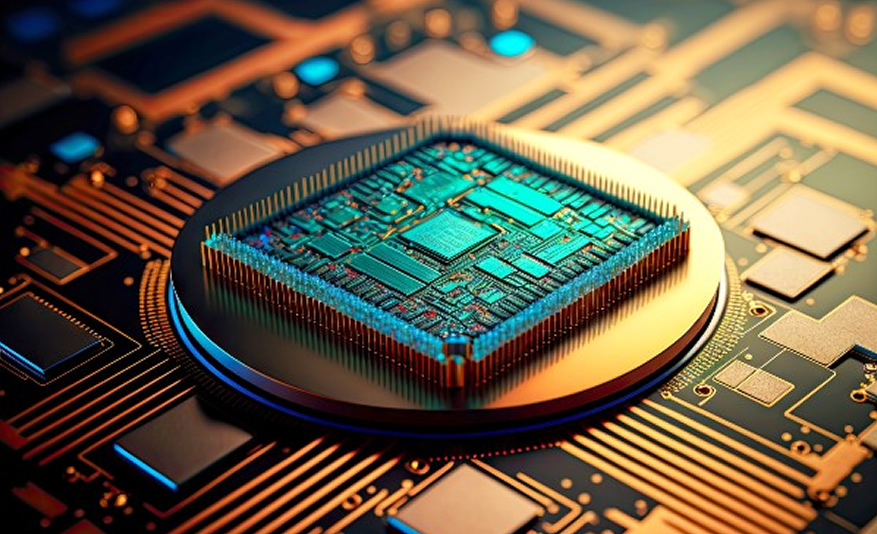

In the process of manufacturing colored printed circuit boards (PCBs), the choice of solder mask color is crucial as it directly relates to the realization of design intentions and the creation of visual appeal. Specifically, the selection strategy can be detailed into the following points:

Enhancing Contrast and Clarity: When the design contains rich details or elements that need to be emphasized, using a solder mask color that forms a sharp contrast with the printing colors is a wise choice. For example, selecting a white solder mask as the base can significantly enhance the clarity and vividness of the color patterns, ensuring that every detail stands out.

Promoting Overall Coordination and Design Unity: Sometimes it is more appropriate to choose a solder mask color similar to the printing colors. This strategy helps build visual coherence, making the patterns and the circuit board whole.

Meeting Personalized Aesthetic and Design Needs: Deciding on the solder mask color often requires considering specific aesthetic preferences and design requirements. In some projects, it may be explicitly stipulated that the solder mask color should match the colored printing parts or create a particular visual effect. In such cases, flexibly applying color-matching principles is key to realizing the design effect.

Special Tip: For situations where the entire Top or Bottom side requires color printing, regardless of the solder mask color you choose, PCBWay will use a white solder mask as the base on the entire color-printed side for better results. This practice is based on the excellent coverage and color fidelity of white solder masks, which can effectively ensure the vividness and accuracy of color printing. It helps avoid issues of dull colors, distortion, or deviation from the design intent due to differences in the base color.