The automotive industry is undergoing a significant transformation as manufacturers strive for lighter, more efficient, and high-performance vehicles. One material that is playing a pivotal role in this shift is carbon fiber sheets. Once reserved for high-end racing cars and aerospace applications, carbon fiber is now becoming a key player in mainstream automotive manufacturing. In this article, we’ll explore how carbon fiber sheets are revolutionizing the automotive industry and driving innovations in vehicle design, performance, and sustainability.

1. Reducing Vehicle Weight for Improved Efficiency

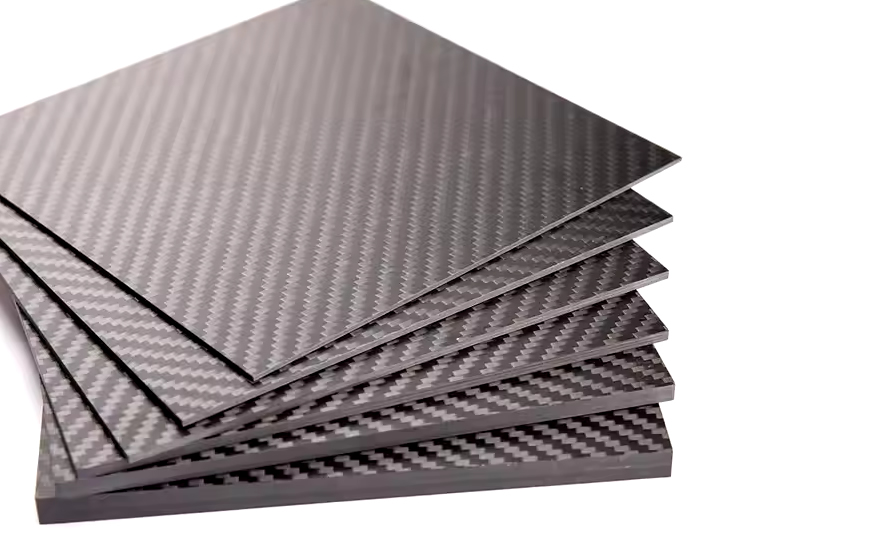

One of the primary reasons carbon fiber sheets are gaining traction in the automotive industry is their exceptional strength-to-weight ratio. Carbon fiber is much stronger than steel but weighs significantly less. By replacing heavier materials like steel and aluminum with carbon fiber sheets, manufacturers can significantly reduce the weight of vehicles.

For example, the lighter a vehicle is, the less energy is required to move it, which directly translates to better fuel efficiency. This is particularly important as automakers face increasing pressure to meet stricter fuel economy standards and reduce carbon emissions. Lighter vehicles also have improved acceleration, handling, and braking performance, making carbon fiber a desirable material for performance vehicles as well as everyday cars.

2. Enhancing Vehicle Safety

While reducing vehicle weight is crucial for efficiency, safety remains a top priority in automotive design. Carbon fiber sheets contribute to improving crash safety without compromising on strength. Carbon fiber is extremely rigid and can absorb significant amounts of energy in the event of a collision, thereby reducing the risk of injury to passengers.

Manufacturers can design carbon fiber components to be strategically placed in the vehicle’s structure to enhance impact resistance, making it an ideal material for critical areas like the passenger cabin, bumpers, and crumple zones. This makes carbon fiber sheets not only a performance booster but also a safety enhancement for modern vehicles.

3. Boosting Performance in High-End Vehicles

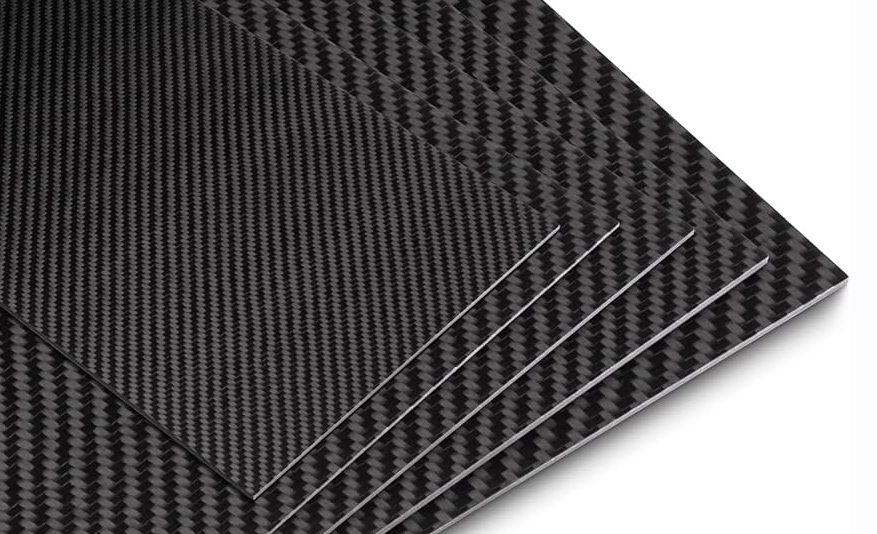

carbon fiber sheets are particularly popular in high-performance and luxury vehicles. The automotive world has long used carbon fiber for components like spoilers, hoods, and body panels to reduce weight without sacrificing strength. However, the use of carbon fiber is now expanding to more parts of the vehicle, including structural components and entire chassis.

Take, for example, the BMW i3 and McLaren P1, both of which feature extensive use of carbon fiber in their construction. The use of carbon fiber allows for more agile, responsive driving experiences, with enhanced handling, stability, and acceleration. Carbon fiber’s ability to withstand extreme conditions, such as high speeds and high temperatures, makes it the perfect material for vehicles that push the limits of performance.

4. Sustainability and Fuel Efficiency

As the automotive industry shifts toward sustainability, carbon fiber sheets offer significant environmental advantages. The reduction in vehicle weight leads directly to lower fuel consumption and fewer carbon emissions. For electric vehicles (EVs), lighter materials such as carbon fiber are essential for increasing the range of the battery, as they help to reduce the energy consumption of the vehicle.

Additionally, the growing trend of carbon fiber recycling is helping make the material more sustainable. Advances in recycling technologies are allowing manufacturers to recover and reuse carbon fiber, reducing the environmental impact of production and disposal. As automakers increasingly focus on reducing their carbon footprint, carbon fiber sheets are playing a key role in building greener vehicles.

5. Design Flexibility and Aesthetics

Carbon fiber sheets offer a level of design flexibility that traditional materials cannot match. Carbon fiber can be molded and shaped into complex forms, allowing automakers to design more aerodynamic and aesthetically appealing vehicles. Its sleek, modern look has become synonymous with high-performance vehicles and is often used as a design element in both the interior and exterior of vehicles.

Carbon fiber’s ability to be customized also means that automakers can experiment with innovative shapes and forms, leading to cutting-edge designs that were previously impossible with heavier materials. The automotive industry is taking advantage of this flexibility to produce more efficient, futuristic vehicle designs that appeal to both performance enthusiasts and environmentally conscious consumers.

6. Improved Durability and Longevity

Carbon fiber sheets are not only lightweight but also incredibly durable. Unlike steel and aluminum, which can corrode or degrade over time, carbon fiber is highly resistant to environmental damage. It is impervious to rust, and its ability to withstand moisture, UV radiation, and extreme temperatures ensures that vehicles made with carbon fiber have a longer lifespan and require less maintenance.

For manufacturers, this durability translates to fewer repair costs and greater customer satisfaction, particularly in vehicles that are exposed to harsh driving conditions or are used for extended periods.

7. Cost and Production Challenges

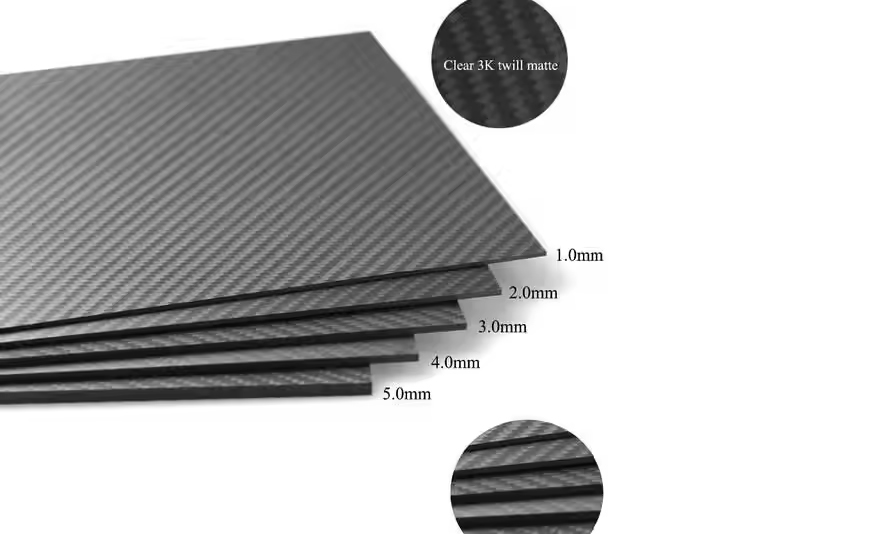

While the benefits of carbon fiber sheets are clear, the material has traditionally been more expensive than steel or aluminum, which has limited its use in mainstream production vehicles. However, advances in manufacturing technology are beginning to drive down costs, making carbon fiber more accessible for a wider range of vehicles.

For example, the development of automated fiber placement (AFP) and resin transfer molding (RTM) processes has made it possible to manufacture carbon fiber parts at a lower cost and with greater efficiency. As the technology matures and economies of scale come into play, carbon fiber will become increasingly cost-effective, and its use in everyday vehicles will become more common.

8. Future Prospects: Carbon Fiber in Electric and Autonomous Vehicles

The rise of electric and autonomous vehicles (EVs and AVs) is poised to further accelerate the use of carbon fiber sheets in the automotive industry. As EVs become more mainstream, reducing vehicle weight becomes crucial to improving energy efficiency and increasing the range per charge. Carbon fiber is the perfect material to meet these demands.

Moreover, as autonomous vehicles require sophisticated sensor systems, carbon fiber sheets can be used to house and protect these technologies while keeping the vehicle lightweight. The future of carbon fiber in automotive manufacturing looks bright, with increasing integration into both electric and autonomous vehicle platforms.

Conclusion

Carbon fiber sheets are changing the landscape of the automotive industry by offering a combination of lightweight strength, enhanced performance, increased safety, and sustainability. From high-performance sports cars to eco-friendly electric vehicles, carbon fiber is helping automakers meet the demands of modern consumers while pushing the boundaries of innovation.

As technology improves and costs decrease, it’s likely that carbon fiber sheets will become even more widespread in automotive manufacturing, helping to drive the future of transportation toward lighter, more efficient, and safer vehicles. For automakers, embracing carbon fiber now not only positions them at the forefront of industry innovation but also helps them meet the growing demands for performance, sustainability, and design excellence in the years to come.