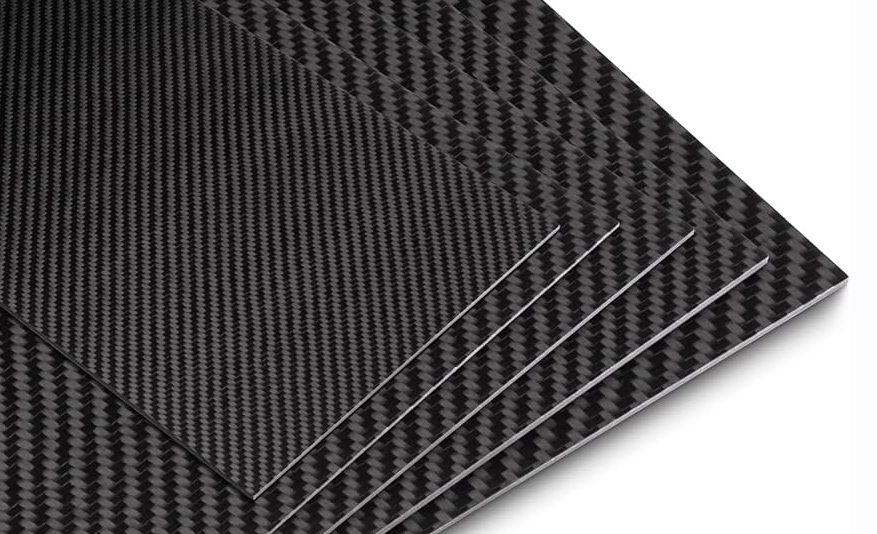

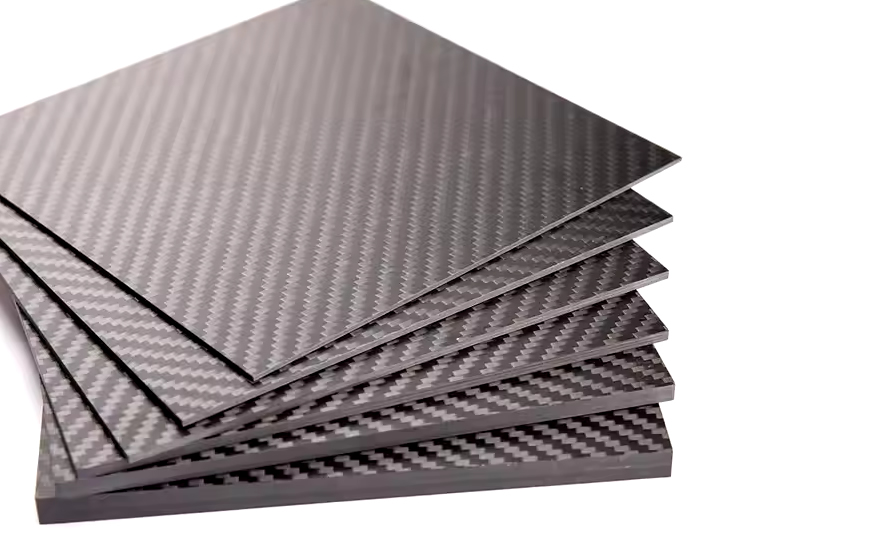

Carbon fiber sheets are becoming an increasingly popular material in various industries, especially in manufacturing. Known for their lightweight yet incredibly strong properties, carbon fiber sheets offer a wide range of benefits that can enhance product performance, reduce costs, and open up new possibilities in design and production. In this article, we’ll explore the key advantages of using carbon fiber sheets in manufacturing and why they are an excellent choice for a variety of applications.

1. High Strength-to-Weight Ratio

One of the most significant advantages of carbon fiber sheets is their remarkable strength-to-weight ratio. Carbon fiber is much stronger than steel and other metals, yet it is incredibly lightweight. This property makes it an ideal material for industries where reducing weight without sacrificing strength is essential.

For example, in the aerospace, automotive, and sports industries, reducing weight while maintaining structural integrity can lead to improved performance, greater fuel efficiency, and better handling. Carbon fiber sheets help manufacturers create parts and components that are both lighter and stronger than traditional materials.

2. Durability and Longevity

Carbon fiber is known for its durability. Unlike metals that can corrode or degrade over time, carbon fiber is highly resistant to wear and tear, making it an excellent choice for products that need to withstand harsh environments. Whether in extreme temperatures, moisture, or exposure to chemicals, carbon fiber sheets maintain their strength and performance over extended periods.

This long lifespan not only reduces the need for frequent replacements but also makes carbon fiber an economically viable option in the long run, especially for high-performance applications like automotive parts, aerospace components, and industrial machinery.

3. Corrosion Resistance

In industries such as marine manufacturing or chemical processing, corrosion is a significant concern. Carbon fiber sheets do not rust or corrode like metals, which makes them an excellent choice for products exposed to moisture or chemicals. This resistance to corrosion can extend the life of products, reduce maintenance costs, and improve the safety and reliability of components used in challenging environments.

For example, in the production of marine equipment like boat hulls or watercraft components, carbon fiber sheets offer a long-lasting, corrosion-resistant alternative to traditional materials like aluminum or steel.

4. Design Flexibility

The versatility of Carbon fiber sheets extends to their design potential. Carbon fiber can be molded into complex shapes and sizes, which allows manufacturers to create highly customized products. This design flexibility is especially valuable in industries like automotive and aerospace, where parts often need to be lightweight yet strong and aerodynamically efficient.

Carbon fiber sheets can be easily cut, formed, and shaped to meet specific performance requirements, enabling manufacturers to optimize their designs for functionality and aesthetics. As a result, carbon fiber is often used in high-end products such as luxury cars, performance bicycles, and cutting-edge sports equipment.

5. Thermal Stability

Carbon fiber sheets offer excellent thermal stability, meaning they can withstand extreme temperatures without warping, expanding, or losing their structural integrity. This makes them ideal for applications where heat is a concern, such as in the aerospace, automotive, and electronics industries.

For instance, in the production of heat shields or engine components, carbon fiber sheets can maintain their shape and strength even in high-heat environments, ensuring that the final product continues to perform reliably over time.

6. Improved Manufacturing Efficiency

Another significant benefit of using carbon fiber sheets in manufacturing is the potential for improved production efficiency. Carbon fiber materials are lightweight and can be processed more quickly than traditional metals, resulting in faster production times and reduced labor costs.

Additionally, carbon fiber sheets can often be molded and formed with fewer steps compared to metals, which streamlines the manufacturing process. This efficiency allows manufacturers to meet tight deadlines, lower production costs, and improve overall productivity.

7. Reduced Environmental Impact

As industries increasingly focus on sustainability and reducing their environmental impact, carbon fiber sheets are emerging as a more eco-friendly option. While the production of carbon fiber can still be energy-intensive, its light weight contributes to lower fuel consumption and greenhouse gas emissions, especially in industries like aerospace and automotive.

In the long term, products made with carbon fiber sheets can help reduce the environmental impact of transportation and other energy-consuming applications by improving efficiency and performance.

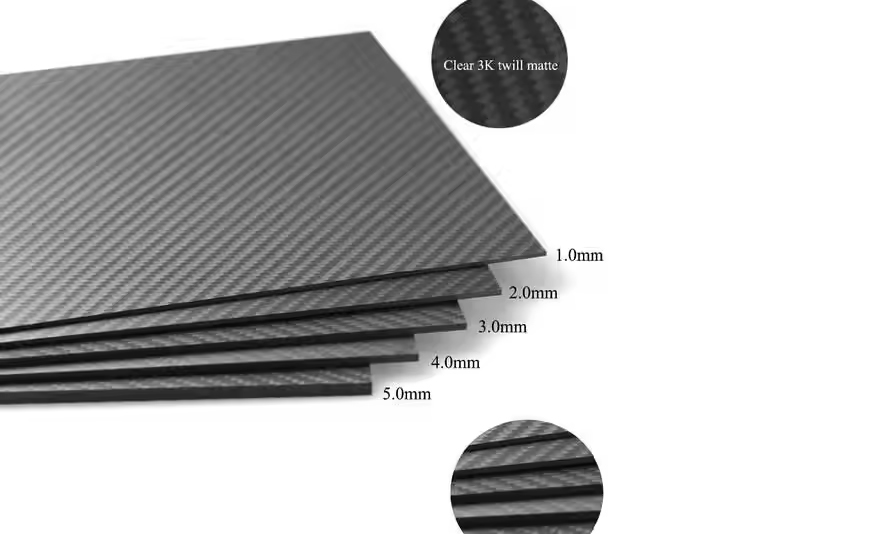

8. Customization and Precision

Carbon fiber sheets offer high precision and can be customized to meet specific strength, stiffness, and weight requirements. This level of control over material properties is particularly important in sectors like aerospace, defense, and electronics, where every detail of a component must be optimized for maximum performance.

Manufacturers can adjust the layup of carbon fiber sheets to achieve the exact balance of properties needed for a particular application, ensuring that components are both lightweight and structurally sound.

Conclusion

Carbon fiber sheets are transforming manufacturing across multiple industries, offering a combination of strength, durability, design flexibility, and performance that traditional materials cannot match. Whether it’s reducing weight in automotive manufacturing, enhancing durability in marine applications, or enabling precision in aerospace, carbon fiber sheets provide manufacturers with a superior material that is both cost-effective and sustainable.

By incorporating carbon fiber sheets into their production processes, manufacturers can achieve better performance, lower costs, and create products that are more reliable and longer-lasting. As the technology continues to advance, carbon fiber will undoubtedly play an even larger role in shaping the future of manufacturing.

If you're considering incorporating carbon fiber sheets into your manufacturing processes, now is the time to explore the many benefits they can offer.