When it comes to selecting the right carbon fiber sheets for a specific project, several factors come into play. The material’s unique properties—such as its strength-to-weight ratio, stiffness, and durability—make it a popular choice for a wide variety of industries, from aerospace and automotive to construction and sports equipment. However, with a range of options available, it's essential to choose the right type of carbon fiber to ensure optimal performance and efficiency for your application. In this guide, we will explore the key considerations to help you choose the best carbon fiber sheets for your project.

1. Understand Your Project's Requirements

Before diving into specific types of carbon fiber sheets, it's crucial to have a clear understanding of your project’s needs. Here are a few questions to ask:

What is the primary function of the component?

Will it need to bear heavy loads, resist high temperatures, or maintain flexibility? Different applications require different properties in the material.What environmental conditions will the material be exposed to?

Will the component be used in harsh environments like high temperatures, extreme humidity, or exposure to chemicals? Some carbon fiber sheets are designed with special coatings or resins to withstand specific conditions.How much weight reduction is necessary?

If weight reduction is a priority (e.g., in the aerospace or automotive industries), choosing a lightweight but strong material will be essential.

Once you have a clear understanding of these parameters, you'll be better prepared to select the right type of carbon fiber sheets.

2. Types of Carbon Fiber Sheets

There are different types of carbon fiber sheets based on their construction, resin systems, and finish. Here’s a breakdown of the main types you’ll encounter:

1. Plain Weave Carbon Fiber

- Appearance: Features a simple crisscross pattern where each fiber alternates between over and under the adjacent fibers.

- Properties: Offers a balanced combination of strength, flexibility, and aesthetic appeal.

- Use Cases: Ideal for a wide range of applications including automotive parts, sports equipment, and decorative finishes.

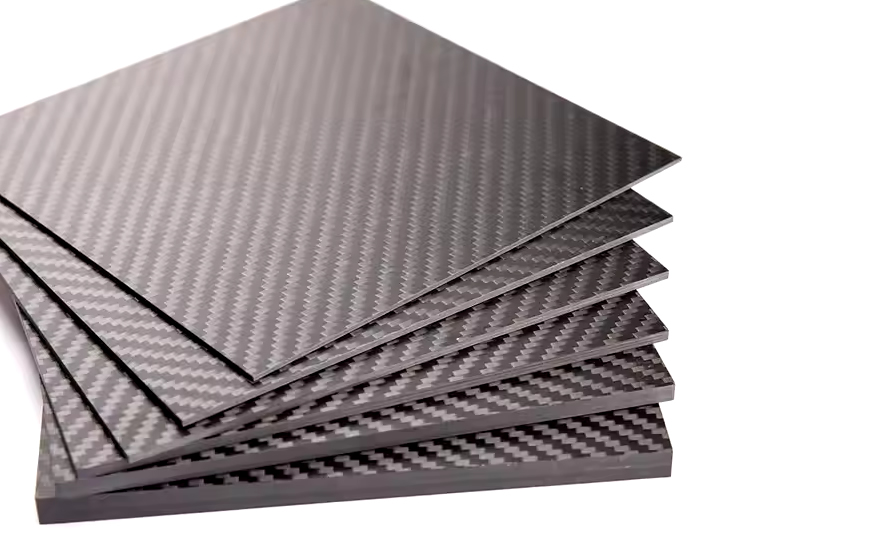

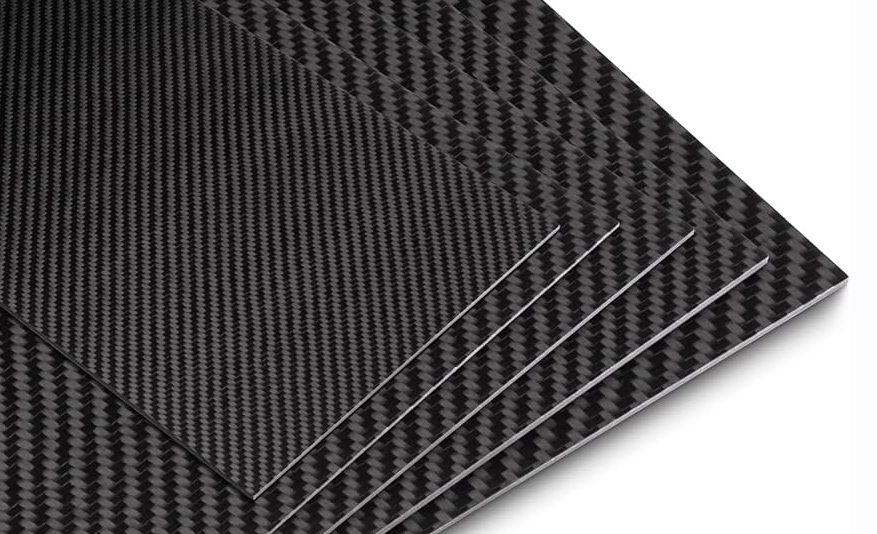

2. Twill Weave Carbon Fiber

- Appearance: Features a distinctive pattern with fibers that weave over and under multiple strands at a time (usually two or four).

- Properties: Known for its higher flexibility and smoother texture, twill weave is often more aesthetically pleasing than plain weave.

- Use Cases: Used in high-end consumer products like bicycle frames, automotive parts, and certain aerospace components.

3. Unidirectional Carbon Fiber

- Appearance: The carbon fibers run in a single direction, which provides high strength along that axis but little resistance to stress in other directions.

- Properties: Offers maximum strength and stiffness along the direction of the fibers, but is weaker in perpendicular directions.

- Use Cases: Used in applications where strength in a single direction is critical, such as structural reinforcement or load-bearing parts.

4. Bi-Axial and Tri-Axial Carbon Fiber

- Appearance: The fibers are oriented in two or three directions to provide enhanced strength and stability in multiple axes.

- Properties: Provides improved performance under stress in more than one direction, making it stronger and more rigid than unidirectional sheets.

- Use Cases: Common in aerospace and automotive applications where multidirectional strength is required, such as composite panels or structural elements.

5. Prepreg Carbon Fiber Sheets

- Appearance: These are carbon fiber sheets pre-impregnated with resin. This makes them more convenient to work with since the resin is already applied.

- Properties: Offers higher uniformity in terms of resin content, better strength, and more precise control over the curing process.

- Use Cases: Popular in high-performance applications like aerospace, motorsports, and advanced sports equipment.

3. Consider the Resin System

The resin system used in carbon fiber sheets significantly affects the material's performance, strength, and longevity. The most common resin systems include:

- Epoxy Resin: Known for excellent strength, durability, and thermal resistance. It’s the most widely used resin in high-performance carbon fiber applications.

- Polyester Resin: More cost-effective and easier to handle than epoxy, but it offers lower performance in terms of durability and thermal resistance.

- Vinyl Ester Resin: Provides better resistance to chemical exposure and moisture than polyester, though it may be less durable than epoxy in other respects.

When choosing the right resin system, consider factors like the operating temperature, environmental conditions, and expected lifespan of the final product.

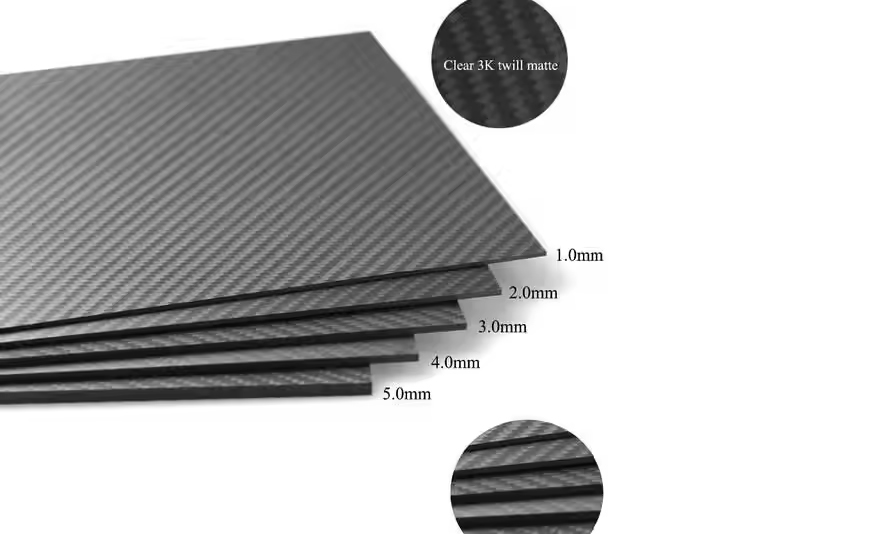

4. Weight and Thickness of Carbon Fiber Sheets

Carbon fiber sheets come in varying weights and thicknesses, and the ideal weight and thickness for your project will depend on several factors:

- Lightweight Components: If weight reduction is a key factor (as in aerospace or automotive applications), look for thin, lightweight sheets with low fiber content (e.g., 3K, 6K, or 12K carbon fiber).

- Structural Strength: If you need a component to bear heavy loads, you may need a thicker sheet with a higher fiber content.

Typical weights range from 100 gsm (grams per square meter) to 400 gsm, with thicker sheets offering more strength and durability. For complex shapes, 3D-formed sheets may be necessary to accommodate curves and bends without compromising strength.

5. Surface Finish

The surface finish of the carbon fiber sheet can be an important consideration depending on your application. Common finishes include:

- Glossy Finish: Offers a sleek, shiny look, often used in luxury products, sports cars, and consumer electronics.

- Matte Finish: Offers a more industrial look, commonly used in aerospace, military, and construction applications where aesthetic appeal is less important than performance.

The finish will also affect the bonding properties of the material, particularly when bonding to other surfaces. A matte finish often provides better adhesion for paints, coatings, and bonding agents.

6. Cost Considerations

Carbon fiber is a premium material, and its cost can vary significantly depending on factors such as:

- Type of weave (plain, twill, or unidirectional)

- Resin system used

- Thickness and weight of the sheet

- Manufacturing process (prepreg vs. standard lay-up)

Prepreg carbon fiber, for example, can be more expensive due to its specialized resin application, but it offers higher strength and uniformity. Be sure to balance the cost of the material with the performance requirements of your project.

7. Processing and Fabrication Requirements

Consider the ease with which the carbon fiber sheets can be processed. Some key factors include:

- Cutting: Carbon fiber is tough to cut and requires specialized tools (e.g., diamond-tipped blades, CNC machines, or waterjet cutting).

- Molding and Shaping: Prepreg carbon fiber sheets and some woven fabrics are more amenable to molding into complex shapes compared to unidirectional sheets.

- Joining: Carbon fiber can be difficult to bond, so ensure that the resin or bonding agent you use is suitable for the material’s surface properties.

If your project involves complex shapes, intricate designs, or high-volume production, it may be beneficial to consult with a carbon fiber supplier or manufacturer to ensure you select the right sheet and processing method.

Conclusion

Choosing the right carbon fiber sheets for your project involves understanding the material's properties, considering the specific requirements of your application, and weighing factors like resin system, weave pattern, thickness, and cost. Whether you're designing high-performance aerospace components, automotive parts, or lightweight structural elements, carbon fiber's superior strength-to-weight ratio, durability, and versatility make it an ideal choice for a wide range of projects.

By carefully assessing your project’s needs and matching them with the appropriate carbon fiber characteristics, you can ensure that the material you select delivers the best performance, longevity, and cost-efficiency for your application.