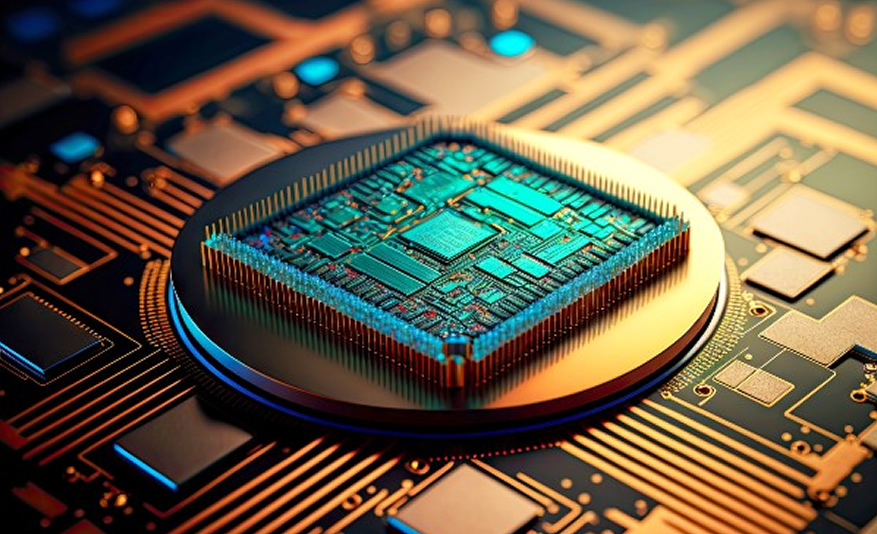

It's common knowledge that lifecycle management for machines can save time, effort and resources. It can also increase reliability, decrease unplanned downtime and extend the life of machines. The same is true for automation components including PLCs, robots and HMIs. Lifecycle management at the component level? Yeah, that's a thing.

Global disruptions, such as nationwide labor shortages, loss of experienced personnel and margin pressures, are driving the adoption of lifecycle management down to the component level. Digital transformation technologies are increasing demand and creating capacity issues. It's all converging to the point where original equipment manufacturers (OEMs) need a better way forward. In other words, if an OEM’s core competency is product innovation and design, and they’re hemorrhaging experienced engineers and can't find replacements, they need to rethink the way things are done.

Having high-quality automation components is not enough. Advanced engineering software is now an essential ingredient for remaining competitive. When selecting engineering software, look for these essential attributes.

- A single programming environment for every phase of development - from design, to programming, debugging and maintenance

- Advanced diagnostics for quickly identifying, communicating and resolving issues even before team members arrive at the machine

- Advanced simulators that not only let you simulate the PLC logic but also the HMI and 3D digital twins

With the right software, you can address challenges across the lifecycle of the component. When the right software is used—during the design stage and through startup, the operating stage and during optimization—you can accelerate time-to-market, reduce commissioning time, cut downtime and maintenance costs, and optimize runtime and overall equipment effectiveness (OEE).

The design stage is all about reducing time-to-market. For the Design Stage, look for these time-savers: intuitive drag-and-drop functionality, custom function blocks & libraries, advanced simulation and a modern HMI.

The startup stage is all about reducing time to commission. One way to reduce commissioning time is to create easy access to the data needed to fine-tune your machine to the application's needs. Web pages and other user interface tools give you access to the information needed to make adjustments. They can also tell you how those adjustments have affected your process. For the startup stage, look for a system recorder module, HMI and VFD/Servo templates, PLC and HMI web server visualization, custom web pages and interfaces and support for multiple languages.

During the operating stage, reducing downtime is key. All machines will go down at some point. Your software should have advanced diagnostic tools that help you quickly identify, communicate and offer resolutions to team members before they even arrive at the machine. An important capability in this stage is event recorder modules that fully record and sync up the program state changes (electrical) and a camera (mechanical) for a set amount of time before and after an event takes place. An event recorder module uses the PLC program, HMI software and a camera to observe the events leading up to an error.

Other key capabilities to look for include predictive maintenance, HMI backup and restore, enterprise system integration and HMI mobile and reporting capabilities.

The final stage, optimization, is all about having actionable data to drive intelligent business decisions. For this stage, look for advanced process optimization and advanced data collection, reporting and analysis. Since optimization is a cyclical process, there is always room for improvement.

Component-level lifecycle management makes trouble-free engineering possible. It can improve every phase of development and help you deliver high-quality, low-maintenance machines at scale. It can also help you mitigate risk in the technology lifecycle, extend your machine's period of profitability, lower service costs with predictive maintenance and increase customer loyalty.