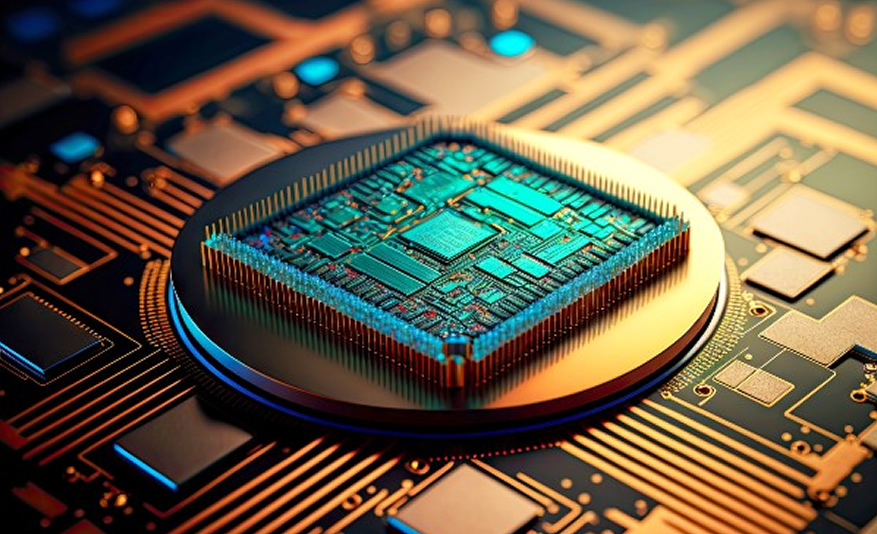

FESTO recently introduced its latest innovation in the form of the Valve Terminal VTUX. This innovation marks the beginning of a new era in valve terminals with its features making it an impressive solution for the future.

“Since our groundbreaking introduction of the world’s first valve terminal back in 1987, we have developed numerous other terminals, each with its own specific focus. Thus, our adaptable Valve Terminal VTUX draws on years of experience and offers a highly expandable solution, enabling Festo customers to stay ahead of the ever-evolving technical changes in machine generations, from digitalisation, and cloud connectivity to machine design issues,” says Skye Prato, business unit manager at Festo South Africa.

The valve terminal seamlessly amalgamates the advantages of three classic valve terminals ranges that have set waves in industry: CPV, MPA-L/S and VTUG, into a single user-friendly system.

This solution offers an impeccable combination of cost-effectiveness and advantages, leaving no room for doubts.

It features an intuitive, modular configuration of essential functions, superior performance, and effortlessly integrable capabilities, all of which can be easily incorporated into the smallest of spaces.

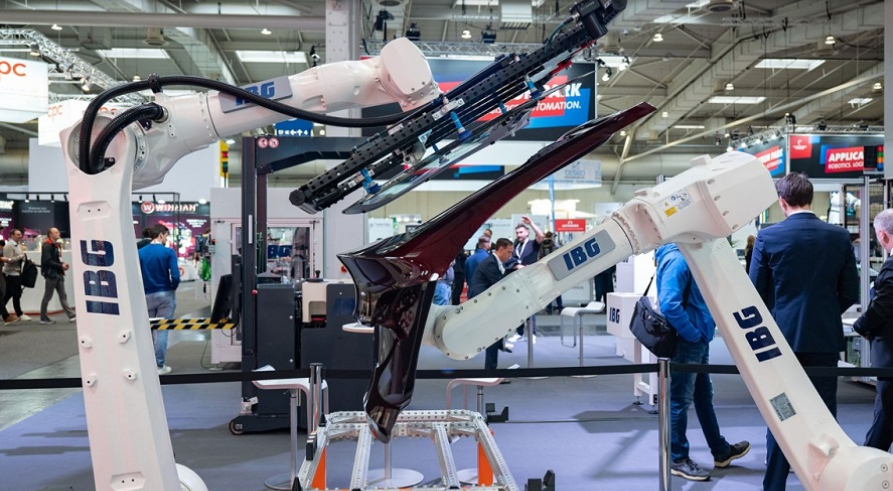

A closer look at the simplified disassembly and design of the VTUX from an expert

During a recent conversation with Skye Prato, the Valve Terminal VTUX took centre stage, as he delved into the valve terminals disassembly process, providing valuable insights into its features, upgrades, and versatility for various applications.

Prato’s first point of emphasis was on the disassembling of the valve, highlighting its user-friendly design. With just a few screws and an allen key, users can easily access the valves, making maintenance and troubleshooting a breeze. The modular design allows for effortless removal and replacement of components, minimising downtime and maximising productivity.

One of the most noteworthy upgrades to this technology is its redesigned valves, which have been expertly engineered to deliver higher flow rates and improved efficiency. As a seasoned expert, he further explained how the valve design has been optimised to accommodate larger flows without increasing the footprint. This innovation allows for greater flexibility and scalability, ensuring seamless integration into a wide array of automation processes.

The ultimate slim and lightweight solution

Focusing on portability and convenience, Festo developers have put significant effort into reducing the size and weight of the VTUX valve terminals, a successor to the three previous classic valve terminals. This has resulted in a valve that offers excellent speed, payload and flow characteristics. These terminals are ideal for installation on handling systems or robots, where size and weight can significantly impact performance.

Systematic interlinking

With just one 10 mm valve and a working connection of up to 8 mm, high flow rates of up to 670 l/min can be achieved thanks to this invention. In addition, VTUX offers a spectrum of interlinking plate widths tailored to varying flow demands while employing the same 10mm valve. The two interlinking plate sizes for tubing diameters of 4mm, 6 mm and 8 mm can be combined. Interlinking plates are available in four valves or a single valve configurations as well. The single connecting plates and modular tie rods enable a system that can be expanded as required to be set up within a short period of time.

High-speed communication

The streamlined, high-speed serial communication employed within valve terminals and base plates significantly minimises the need for extensive cabling and tubing, while facilitating seamless integration of functionalities and diagnostic capabilities. VTUX offers a wide array of interfaces supporting various bus systems and communication standards, including IO-Link. Thus ensuring its adaptability, future readiness across diverse electrical networks and machinery setups. Whether deployed centrally in setups with numerous IOs and valve positions or used in decentralised valve terminals, the valve proves to be a versatile solution.