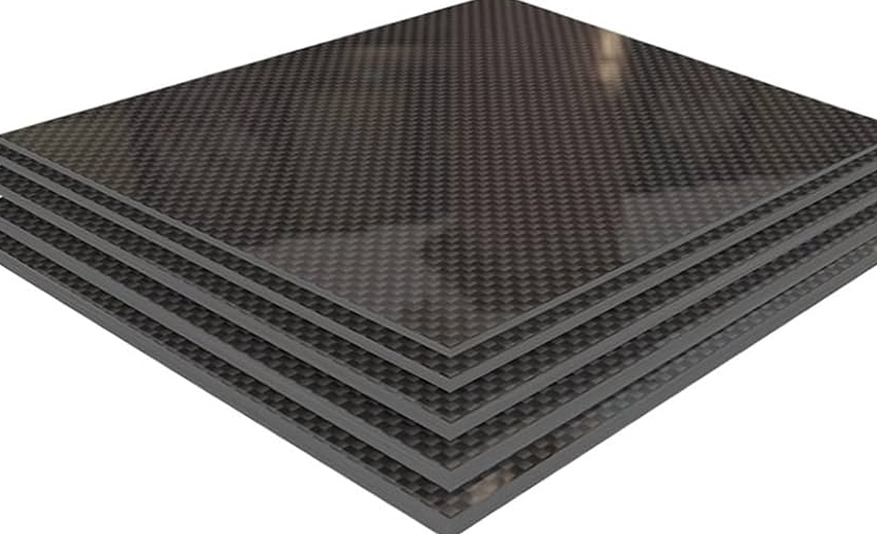

Carbon fiber sheets have gained significant popularity in various manufacturing sectors due to their unique properties and advantages. Here are the top five benefits of using carbon fiber sheets in manufacturing:

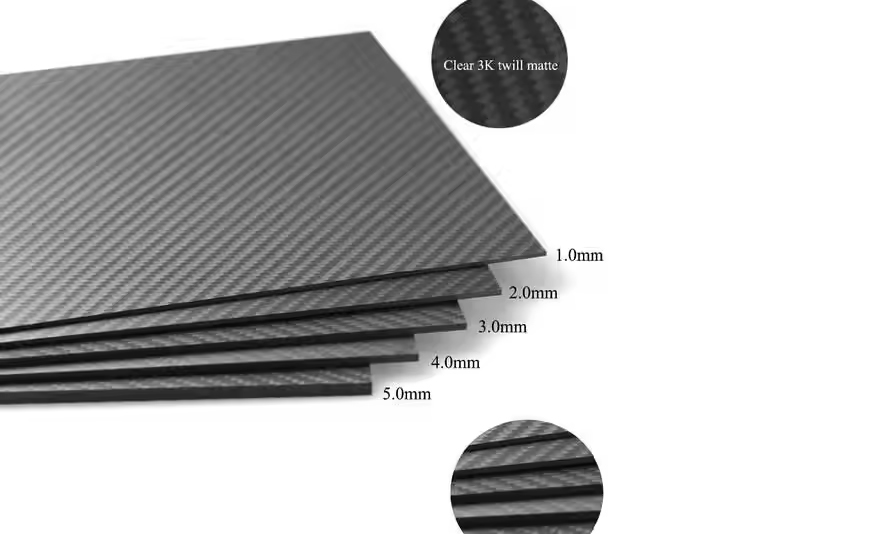

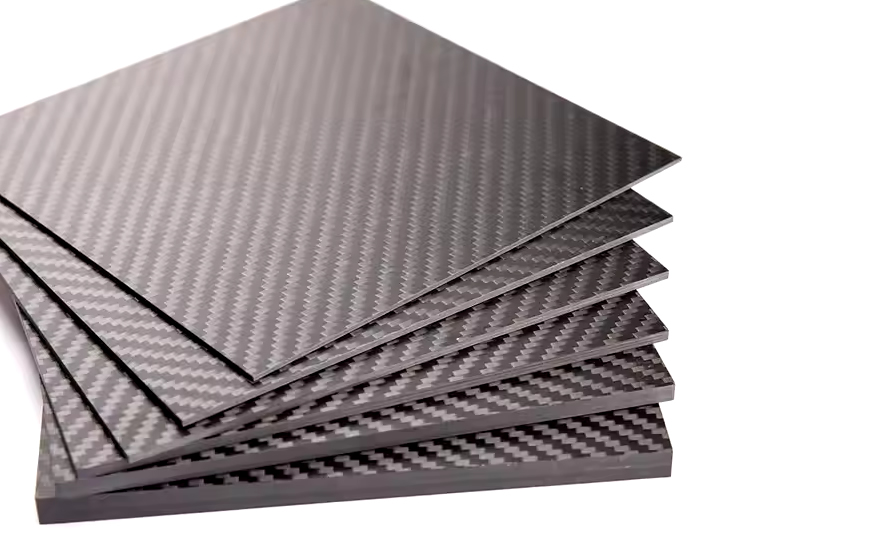

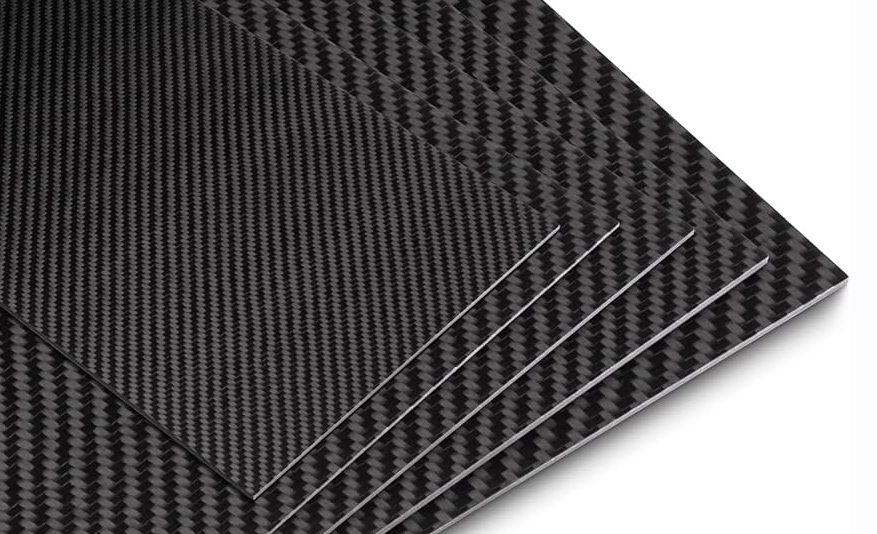

Lightweight yet StrongCarbon fiber sheets are incredibly lightweight, making them an ideal choice for applications where reducing weight is crucial. Despite their lightness, they offer exceptional strength and rigidity, outperforming many traditional materials like steel and aluminum.

High DurabilityThese sheets exhibit remarkable resistance to fatigue, corrosion, and impact, which enhances their longevity in demanding environments. This durability translates into lower maintenance costs and longer service life for products made with carbon fiber sheets.

Versatility in ApplicationsCarbon fiber sheets can be tailored for a wide range of applications, from aerospace and automotive to consumer products and sporting goods. Their adaptability allows manufacturers to customize them to meet specific requirements, making them suitable for both structural and aesthetic uses.

Excellent Thermal and Electrical ConductivityCarbon fiber sheets provide excellent thermal and electrical conductivity, making them suitable for applications that require heat dissipation or electromagnetic shielding. This feature is particularly beneficial in electronics and aerospace industries.

Cost-Effectiveness in the Long RunWhile the initial investment in carbon fiber sheets may be higher than traditional materials, their long-term benefits often outweigh the costs. The combination of durability, reduced weight, and maintenance savings contributes to overall cost-effectiveness in manufacturing processes.

In conclusion, carbon fiber sheets offer significant advantages that can enhance manufacturing processes across various industries. Their lightweight, durable nature, along with their versatility, makes them an excellent choice for modern manufacturing needs.