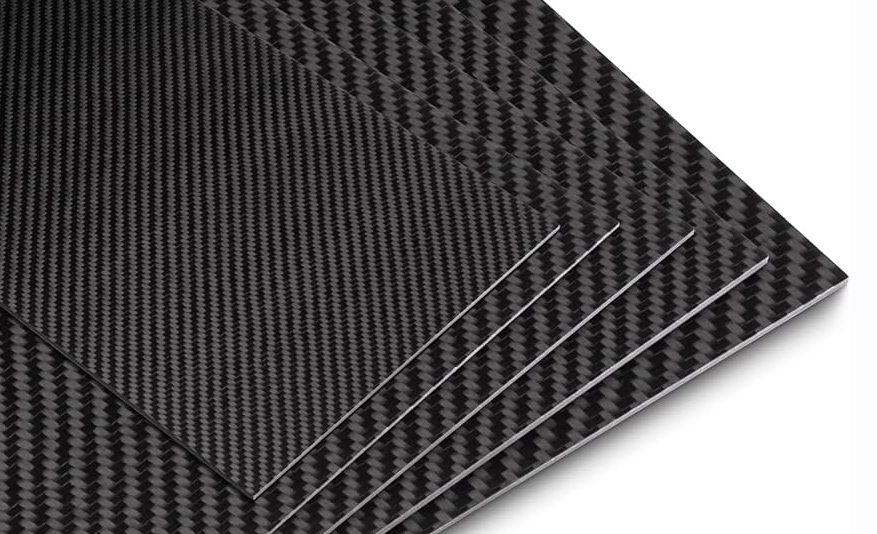

Carbon fiber sheets have emerged as a leading choice for creating lightweight structures across various industries. While the initial investment may be higher compared to traditional materials, the long-term benefits often make them a cost-effective solution. Here’s how carbon fiber sheets provide value in building lightweight structures:

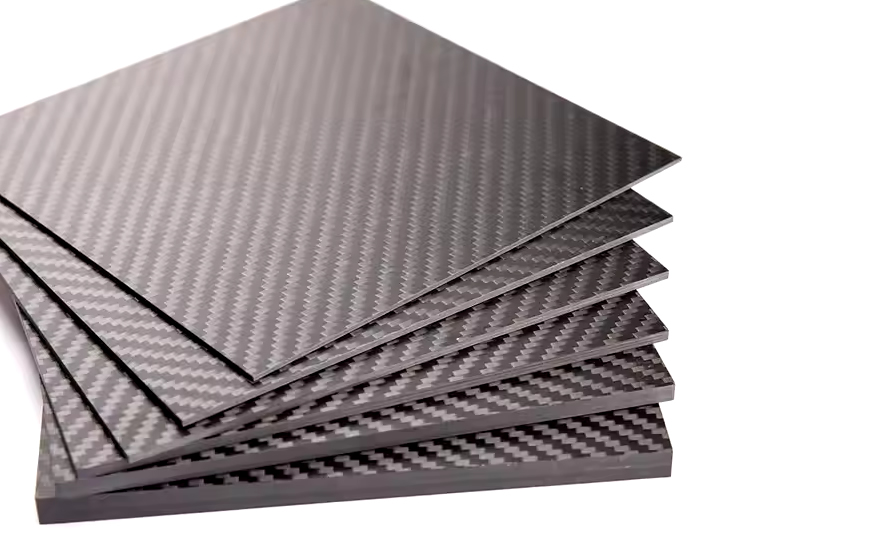

Superior Strength-to-Weight RatioOne of the most significant advantages of carbon fiber sheets is their exceptional strength-to-weight ratio. These sheets are incredibly strong while remaining lightweight, allowing manufacturers to create structures that are both durable and efficient. This property is crucial in applications such as aerospace and automotive, where reducing weight can significantly impact performance and fuel efficiency.

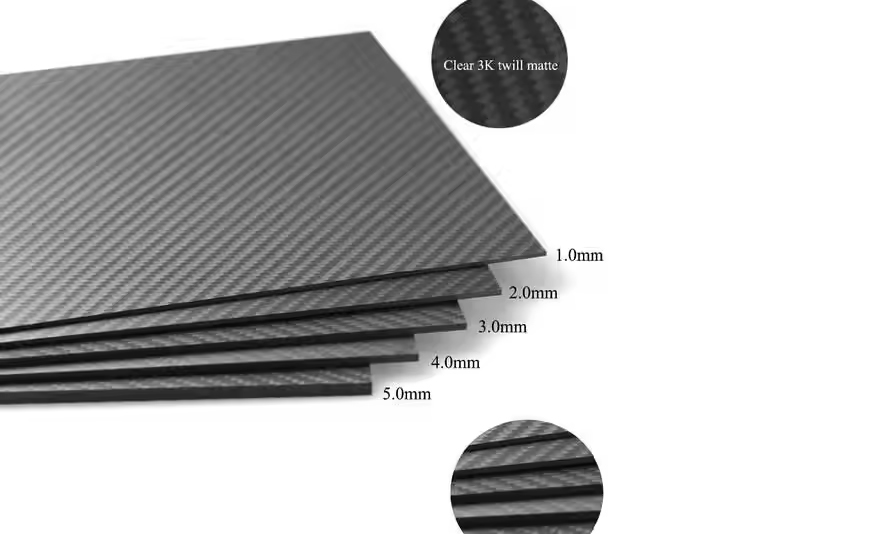

Reduced Material UsageBecause carbon fiber sheets can achieve the required strength with less material, they often lead to reduced overall material usage. This not only lowers material costs but also minimizes waste, contributing to a more sustainable production process. Manufacturers can design thinner structures without compromising safety or performance.

Lower Energy ConsumptionLightweight structures made from carbon fiber sheets require less energy to transport and operate. In the automotive and aerospace sectors, lighter vehicles and aircraft consume less fuel, leading to significant savings in operational costs over time. This reduction in energy consumption aligns with global efforts to reduce carbon footprints.

Durability and LongevityCarbon fiber sheets are highly resistant to corrosion, fatigue, and impact, which enhances the longevity of the structures they form. This durability reduces maintenance and replacement costs, making them a cost-effective option in the long run. Industries that rely on consistent performance, such as construction and transportation, benefit from the reduced downtime associated with traditional materials.

Versatility in DesignThe versatility of carbon fiber sheets allows for innovative design solutions that can optimize performance and aesthetics. Manufacturers can create complex shapes and customized components tailored to specific applications, enhancing functionality without increasing weight. This adaptability can lead to better-performing products that meet market demands.

Customization and TailoringCustom carbon fiber sheets can be engineered to meet specific performance requirements, ensuring that they are suitable for a wide range of applications. This customization can lead to cost savings by allowing manufacturers to design structures that meet precise specifications without over-engineering.

Competitive AdvantageBy adopting carbon fiber sheets in their products, manufacturers can differentiate themselves in the market. The use of advanced materials can enhance product performance and appeal to customers looking for innovative, high-quality solutions. This competitive advantage can lead to increased sales and market share.

Conclusion

Carbon fiber sheets provide a cost-effective solution for lightweight structures, combining superior strength, durability, and design flexibility. While the initial investment may be higher, the long-term benefits, including reduced material usage, lower energy consumption, and enhanced longevity, make them an excellent choice for various industries. As technology continues to advance, the use of carbon fiber sheets is expected to grow, further solidifying their position as a leading material for lightweight structures.