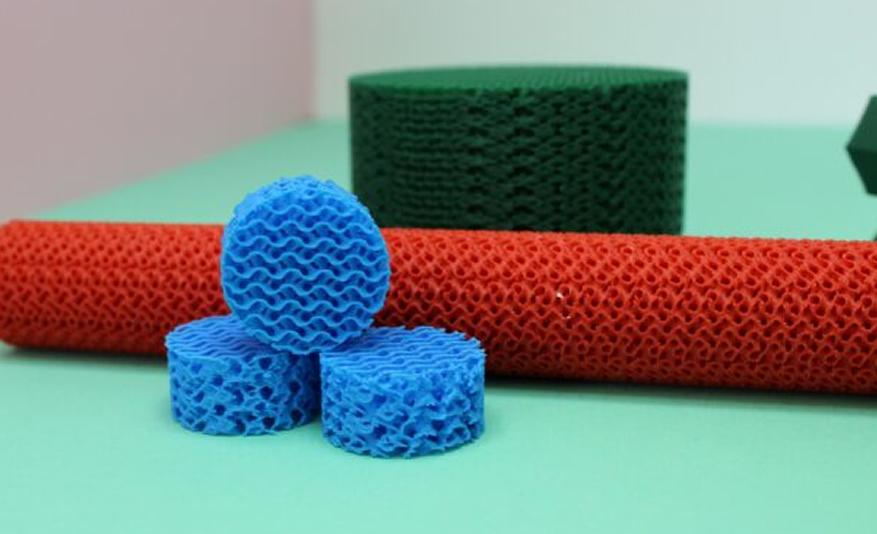

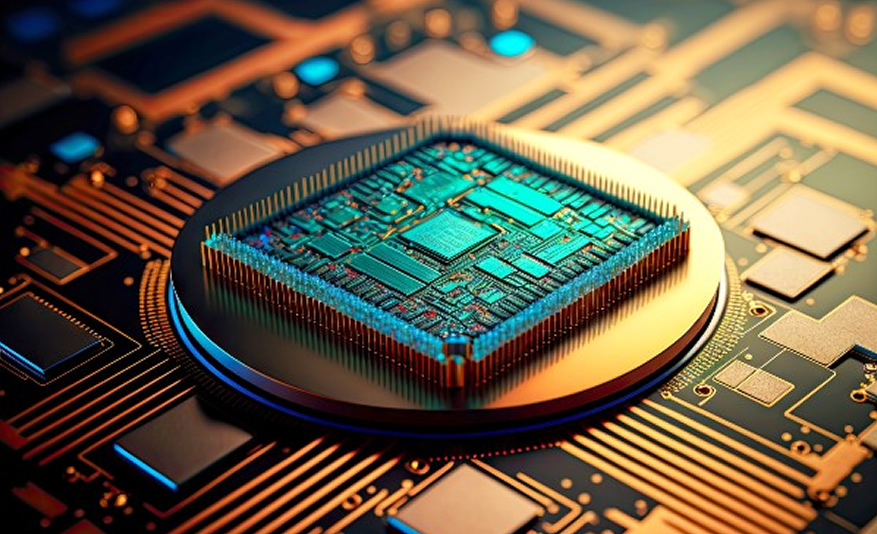

Researchers at the University of Virginia have achieved a remarkable breakthrough in the rapidly evolving field of 3D-printed concrete by creating a more sustainable, printable cementitious composite. This innovative material combines graphene with limestone and calcined clay cement (LC2), resulting in improved strength and durability while dramatically lowering carbon emissions.

This development presents a compelling solution to the environmental challenges facing 3D-printed construction, making it a game-changer for sustainable building practices.

“Our goal was to design a printable concrete that performs better and is more eco-friendly,” said Osman Ozbulut, a professor at UVA’s Department of Civil and Environmental Engineering. “The addition of graphene to LC2 cement offers a unique opportunity to lower carbon emissions while maintaining the strength and flexibility required for 3D printed construction.”

The study, spearheaded by visiting scholar Tuğba Baytak and UVA’s Tawfeeq Gdeh from the Resilient and Advanced Infrastructure Laboratory at the University of Virginia, delved into the flow properties, mechanical performance, and environmental impacts of a groundbreaking material.

In collaboration with researchers from the Virginia Transportation Research Council (VTRC), Baytak and Gdeh incorporated graphene—renowned for its remarkable mechanical attributes—into LC2 cement, significantly enhancing its effectiveness for 3D printing applications.

“This kind of innovation is essential for the future of construction, and I’m proud to be part of the team driving this forward,” said Baytak.

A pivotal element of the research was a Life Cycle Assessment (LCA) conducted by postdoctoral researcher Zhangfan Jiang in conjunction with environmental engineering professor Lisa Colosi Peterson at the University of Virginia. The LCA demonstrated that this graphene-enhanced LC2 concrete could lead to around a 31% reduction in greenhouse gas emissions compared to conventional printable concrete mixtures, highlighting its potential for sustainable construction practices.

“Being able to see the full environmental footprint of this new concrete was important,” explained Jiang. “It not only exhibits better mechanical performance but also has a lower environmental impact, making 3D concrete construction technology more sustainable compared to traditional 3D printing methods with higher carbon emissions.”

“It’s rewarding to see science push us toward greener building practices,” said Colosi Peterson.

The partnership with VTRC allowed the UVA team to explore the material’s applications in transportation infrastructure. “The VTRC collaboration was essential in uncovering the fundamental properties of this new concrete,” added Ozbulut.

“It’s exciting to be part of a project that addresses both the technical demands of modern construction and the urgent need for more eco-friendly materials,” said Gdeh.