Software-defined vehicles (SDVs) represent a paradigm shift in automotive technology, whereby most functions traditionally controlled by hardware are now managed by software. This transition underpins not just enhancements in vehicle functionality but also its adaptability and future upgradability. Central to this evolution are semiconductor devices, particularly wide-bandgap (WBG) semiconductors, which are pivotal due to their superior properties to traditional, silicon-based components. WBG semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), offer exceptional efficiency and high-temperature resilience—critical traits as vehicles become more electric and increasingly autonomous. The integration of these semiconductors is set to significantly influence the development and performance of next-generation vehicles, making them more energy-efficient and robust in diverse operating conditions.

Overview of WBG semiconductors

WBG semiconductors are at the forefront of the next wave of automotive innovations, primarily due to their fundamental properties that allow them to outperform traditional materials. SiC and GaN are the most prominent WBG materials, characterized by their ability to operate at higher voltages, temperatures and frequencies than standard silicon semiconductors. These properties stem from their wide bandgaps: SiC has a bandgap of 3.3 eV and GaN of about 3.4 eV, significantly larger than silicon’s 1.1 eV. This wide bandgap enables the semiconductors to withstand higher electric fields, dissipate heat more efficiently and exhibit reduced electrical losses.

In automotive applications, these characteristics translate into several advantages. Vehicles equipped with SiC and GaN components can achieve greater electrical efficiency, which is crucial for extending the range and reducing the charging time of electric vehicles. Moreover, their high-temperature stability enhances reliability and reduces the complexity and cost of cooling systems within power electronics. As the automotive industry pushes toward more electrified and software-defined platforms, the role of WBG semiconductors becomes increasingly vital, promising to elevate vehicle performance and sustainability to unprecedented levels.

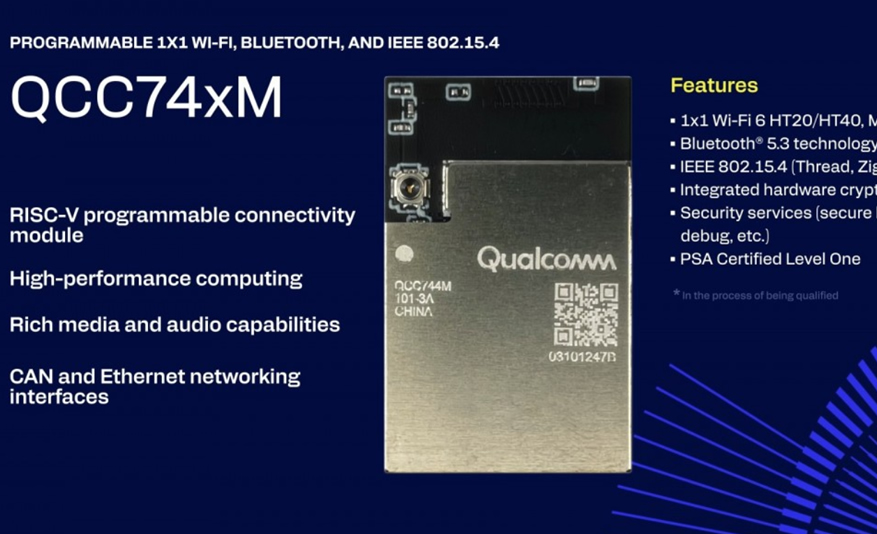

Current applications in vehicles

WBG semiconductors, specifically SiC and GaN, are revolutionizing various aspects of automotive technology through their deployment in power electronics, electric drivetrains and charging systems. These components are pivotal in enhancing EVs’ performance, efficiency and durability:

Power electronics: WBG semiconductors are increasingly used in the inverters that manage the conversion of DC to AC power within EVs. Their ability to operate at higher temperatures and voltages than traditional silicon devices allows for more efficient power conversion, which is crucial for the overall energy efficiency of EVs.

Electric drivetrains: Modern EV drivetrains benefit significantly from the high efficiency and thermal performance of WBG semiconductors. SiC components are employed in the drivetrain systems to handle higher loads and speeds with better efficiency, contributing to longer battery life and reduced energy consumption.

Charging systems: Fast charging is another area substantially impacted by WBG semiconductors. GaN and SiC enable faster switching speeds, which is essential for high-power charging solutions. This capability allows for the development of ultra-fast-charging stations that significantly reduce charging times compared with standard chargers.

Impact on vehicle performance and efficiency

Integrating SiC and GaN into EVs fundamentally enhances vehicle performance, charging capabilities and operational longevity. These improvements are critical as the industry moves toward a more sustainable, efficient and consumer-friendly automotive future:

Enhanced electrical efficiency: WBG semiconductors operate more efficiently than traditional, silicon-based components. This efficiency is crucial in power electronics, where SiC and GaN can minimize the energy lost as heat during electricity conversion from the battery to the motor. This reduction in energy loss ensures that a more significant proportion of the battery’s power is used for propulsion rather than wasted. For instance, the use of SiC in inverters has been shown to improve the efficiency of these units by up to 3%, a significant figure that directly contributes to the overall energy efficiency of the vehicle.

Improved EV range: By enhancing the efficiency of power electronics, WBG semiconductors directly impact the range of EVs. Vehicles equipped with SiC and GaN components can travel longer distances on a single charge than those using standard silicon parts. This improvement in range is a critical factor in the adoption of EVs, as it addresses range anxiety—a significant barrier for many potential EV buyers.

Faster charging speeds: WBG semiconductors also play a critical role in charging technologies. Their ability to handle higher voltages and temperatures allows for faster charging speeds without compromising the integrity of the components. This capability enables the development of rapid charging stations that can recharge an EV’s battery to 80% in as little as 20 minutes, making EVs more practical for longer journeys and reducing downtime for charging.

Extended vehicle lifecycle: The robustness of WBG semiconductors contributes to longer lifecycles for vehicle components. Their ability to withstand harsher environments and manage higher power densities without degradation means that components such as inverters and chargers last longer and require less maintenance over the vehicle’s life. This durability reduces repair and replacement costs and supports the sustainability goals of the automotive industry by minimizing waste.

Challenges and limitations

While WBG semiconductors such as SiC and GaN offer numerous advantages for automotive applications, their integration also presents several challenges that must be navigated:

Technical and economic challenges: One of the primary hurdles is the high cost of WBG semiconductor materials and the complexity of their manufacturing processes. SiC and GaN materials are significantly more expensive than traditional silicon, and their production involves sophisticated fabrication techniques that can increase overall costs.

Integration complexities: Integrating WBG semiconductors into automotive systems demands extensive validation to ensure reliability under diverse operating conditions. Automotive standards are stringent, and any new component, such as a WBG semiconductor, must meet high thresholds for durability and performance across a wide range of temperatures and voltages.

Future trends and developments

The future of WBG semiconductors in the automotive industry looks promising, with several advancements that could further enhance their application in SDVs:

Advancements in technology: Future developments may include improvements in the material properties of SiC and GaN, allowing even higher efficiencies and greater power densities. Researchers are also exploring the possibility of creating new composite materials that combine the best properties of SiC and GaN with other elements to enhance performance and reduce costs.

Impact on automotive design and functionality: As these technologies mature, we can expect them to influence automotive design and functionality significantly. For instance, the enhanced efficiency and reduced size of WBG components may enable designers to create more compact and streamlined vehicle architectures. Furthermore, these semiconductors’ improved power-handling capabilities will support more advanced software-defined features, making vehicles more intelligent and adaptable to individual needs.

Consumer adoption: The ultimate success of WBG semiconductors will depend on their impact on vehicle cost, performance and reliability. As these factors improve, consumer adoption will likely increase, supported by a growing awareness of the benefits of advanced electronic technologies in vehicles.

WBG semiconductors hold transformative potential for the automotive industry, particularly in SDVs. Their superior properties can significantly enhance vehicle efficiency, performance and functionality, aligning with the industry’s move toward more sustainable and intelligent transportation solutions. However, realizing this potential fully requires continued research and development and close collaboration between semiconductor manufacturers and automotive companies. Stakeholders should intensify their efforts to overcome current challenges and drive innovation, ensuring that WBG semiconductors can meet future automotive needs effectively.