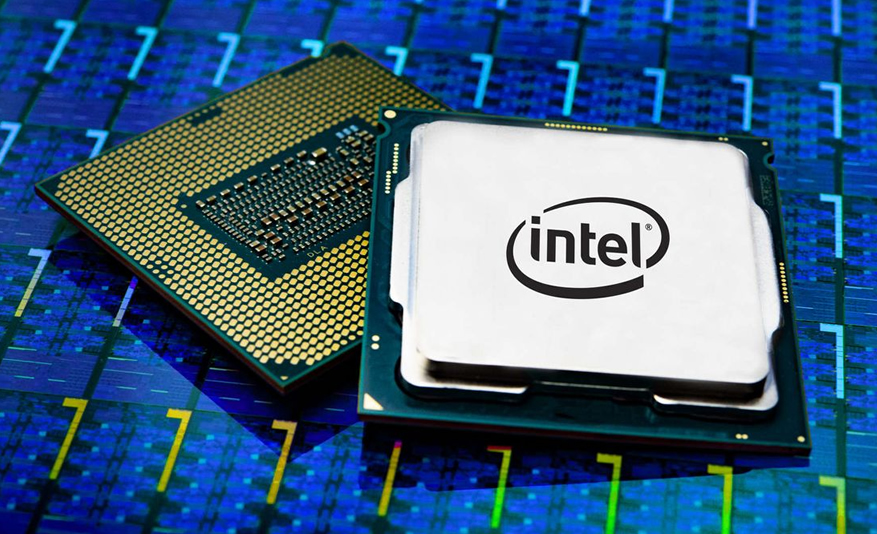

According to industry insiders, Taiwan Semiconductor Manufacturing Company (TSMC) is achieving impressive chip yields at its new factory in Arizona, surpassing those of its similar facilities in Taiwan by around 4 percentage points. This yield is a crucial metric in the semiconductor sector, as it determines the viability of covering the extensive costs of building and operating a chip factory, which can reach tens of billions of dollars for cutting-edge facilities.

As the world's leading chip manufacturer, TSMC has plans to construct three chip factories in Arizona. The company stands to benefit from the U.S. government's CHIPS Act, which offers substantial support, including $6.6 billion in grants, $5 billion in loans, and a 25% tax credit. The CHIPS Act, introduced in August 2022, allocates $52.7 billion to bolster the U.S. chip industry and authorizes $75 billion in government loans.

Originally, TSMC aimed to fully operationalize its first 4-nanometer process technology plant in Arizona by 2024. However, labor issues have postponed this timeline to 2025. The second factory, which will utilize advanced 2-nanometer technology, has its launch delayed to 2027 or 2028, sparking concerns about the Arizona facilities' efficiency compared to those in Taiwan.

Rick Cassidy, President of TSMC’s U.S. division, mentioned the company might consider further expanding its operations in the U.S., contingent on receiving additional government support. The high construction costs in the U.S. necessitate local subsidies, as TSMC founder Morris Chang noted that producing chips in Arizona could be at least 50% more expensive than in Taiwan.