Robotic cable management maximizes your robot’s efficiency in industrial environments. With properly routed wires, your AI-driven robots can perform complex tasks smoothly without interruptions. Good cable management ensures power and data flow consistently, which helps prevent costly breakdowns and delays.

Suppose your robots operate continuously under demanding conditions. Poor cable routing can lead to increased wear and tear, higher maintenance costs and unexpected downtime. Focusing on smart routing practices improves your robot’s performance. It extends its life span, keeping your operations running efficiently and reliably.

Impact of cable routing on AI-driven robotics

Proper routing keeps your AI-powered robots precise, stable and efficient. Mismanaged cables might experience data delays, signal interference or power fluctuations, which can affect your robot’s ability to function accurately. In industries relying on continuous operation – like manufacturing and logistics — minor issues can lead to disruptions that slow the entire process. Good robotic cable management helps maintain stable power and data transmission for high-functioning robots, allowing them to perform complex tasks without missing a beat.

In fact, around 20% of large companies in the EU used industrial robots in 2022, highlighting the growing importance of automation. Poor cable routing has led to malfunctions and costly repairs in sectors like autonomous manufacturing. Meanwhile, in logistics, mismanaged wires can cause power loss or signal disruption, throwing off critical tasks like inventory sorting. Focusing on proper management ensures your robots run smoothly, helps you keep operations efficient and avoids unnecessary downtime.

Advanced cable routing techniques for high-end robotics

Advanced routing solutions — like self-organizing cable trays and dynamic systems — can simplify how you manage complex robotic setups. Self-organizing trays adjust automatically to keep wires in place. At the same time, dynamic systems ensure they stay secure when your robots are in constant motion. Robotic arms with internal cable routing add a layer of protection by shielding them from dust, moisture and other external factors.

These efficient systems make troubleshooting and fixing problems easier and keep your robots scalable so future upgrades are hassle-free. Flexible cable management is crucial, too — it ensures that even with complex movements, your wires stay untangled and reduce wear and tear over time.

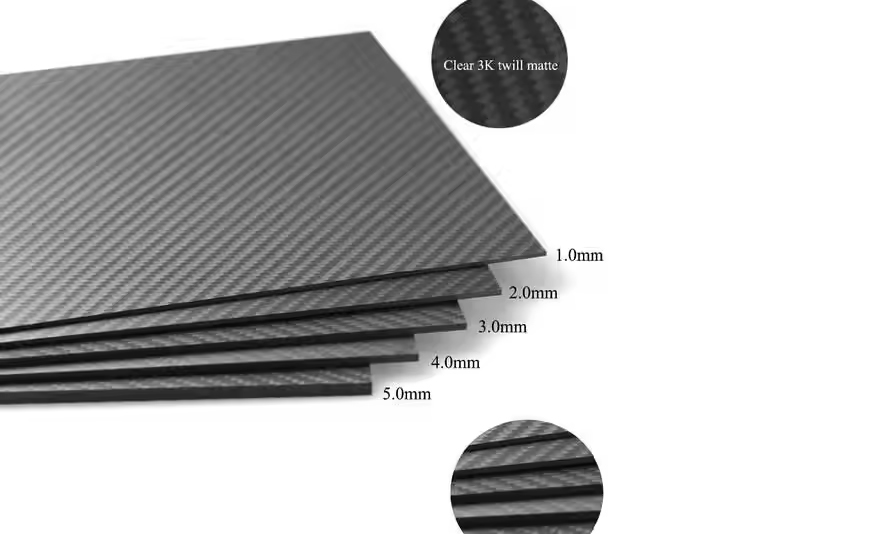

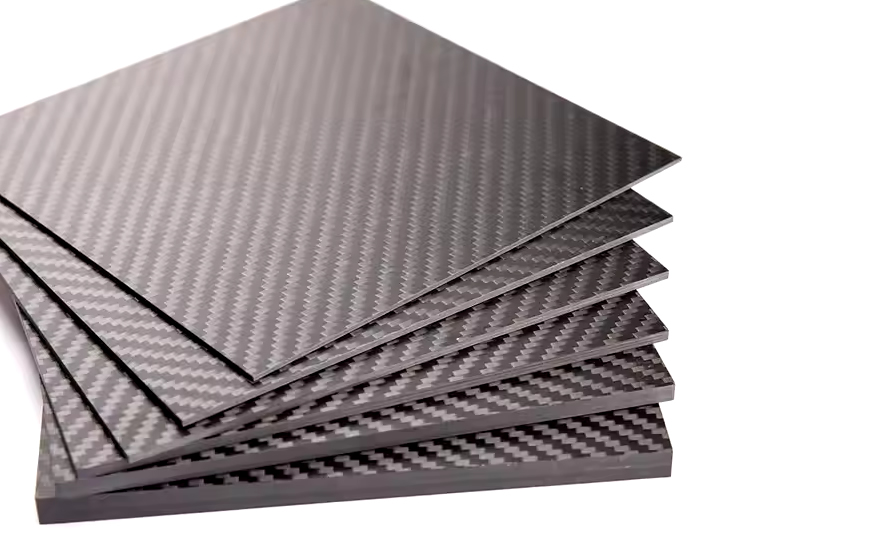

Material science innovations in cable manufacturing

The latest advancements in cable materials are perfect for helping you tackle extreme industrial conditions. Heat-resistant polymers are designed to withstand high temperatures, so your wires stay strong in hot environments like manufacturing. Advanced shielding techniques — such as multi-layered metal shields — protect your cables from electromagnetic interference.

Moreover, wear-resistant coatings help wires survive abrasive conditions, cutting down on replacements and maintenance. Smart materials with self-healing capabilities automatically fix minor damage and adapt to your robots’ movements. These elements ensure your systems run smoothly and stay durable in the harshest conditions.

Predictive maintenance for cable systems using AI

AI-powered predictive maintenance tools are pivotal in keeping your cables in top shape. These tools monitor wear in real time and allow you to prevent failures before they happen. Using machine learning models, they analyze data from sensors embedded in your cables, identify potential failure points and optimize your maintenance schedule. This proactive approach means avoiding unnecessary repairs while catching issues before they cause severe damage. In fact, predictive maintenance can eliminate up to 75% of unexpected breakdowns and lower your maintenance costs by up to 30 percent.

Industries using AI-integrated robots — like manufacturing and logistics — have already seen major benefits from predictive maintenance. Monitoring conditions continuously, these tools have drastically reduced cable-related downtimes and helped businesses keep their operations running smoothly. Instead of reacting to problems as they arise, you can plan maintenance at the right time, reduce disruptions and ensure your robots perform at their best. This saves you money and maximizes the efficiency and reliability of your entire system.

Designing cable systems for scalability and future-proofing

When designing cable systems for AI-powered robots, scalability is crucial to the longevity of your operations. As AI applications evolve and robots take on more complex tasks, your cable system must be flexible enough to handle these upgrades. The rapid growth of data centers and IT facilities — due to the need for secure and affordable connectivity — has increased the demand for robust wire solutions.

Modular cable systems are ideal — they allow you to easily replace or upgrade individual components without overhauling the entire system. You can also consider long-term needs, such as higher data transmission speeds and the addition of new sensors requiring more connectivity. Planning for these future demands can ensure your system remains adaptable and supports your AI robots as they evolve to meet new challenges.

Avoiding common pitfalls in robotic cable management

Even advanced industrial teams can make common mistakes when managing cable systems. One of the most frequent errors is overloading channels, which can cause excess heat buildup, degradation and eventual failure. Another issue is underestimating environmental impacts. Cables exposed to harsh conditions like extreme temperatures, moisture or chemicals can wear down faster than expected.

Additionally, failing to conduct regular, rigorous cable inspections can leave unseen damage unaddressed until it’s too late. As economic growth and access to technology expand globally, there has also been a rise in e-waste generation, which makes efficient and long-lasting cable systems more critical than ever.

Balancing performance and cable system longevity is essential to avoid these pitfalls. Use channels that can handle the electrical load without overheating and choose materials specifically designed for the environmental conditions of your facility. Regular inspections are critical — set a schedule for thorough checks to catch any wear and tear early.

It’s also vital to embrace continuous improvement in cable management strategies, especially as AI and robot technologies evolve. Regularly updating your approach ensures your systems remain scalable and durable, keeping your operations efficient while minimizing the environmental footprint.

Staying ahead with robotic cable management

Embrace cutting-edge cable management technologies and predictive maintenance tools to keep your robots running at peak efficiency. Integrating these innovations can reduce downtime, extend the life of your equipment and streamline operations. Cable advancements drive the next phase of industrial robotics and ensure your systems are ready for future demands.