Using CMOS fabrication, quantum photonics researchers from the U.K.’s University of Bristol have integrated the “world’s tiniest quantum light detector” onto a silicon chip, paving the way to volume manufacturing of photonic integrated circuits (PICs) for quantum communications and computers.

With a footprint of 80 µm × 220 µm and a 3-dB bandwidth of 15.3 GHz, the electronic-photonic integrated detector outperforms a previous cutting-edge quantum detector from the Bristol team. In that earlier work, professor Jonathan Matthews, who heads up the university’s Quantum Engineering Technology (QET) Lab, and colleagues had linked a photonic chip and an electronic chip via electronic wirebond interconnects.

According to Matthews, the new chip is smaller than the previous detector by a factor of 50 but offers an order of magnitude greater bandwidth and exceeds the speed performance of the earlier design. “What we really wanted to explore with this work was how small we could make a quantum-noise-limited detector, and also how fast we could make it go,” he said. “We’ve now broken records with our combined quantum device. It works at room temperature … and [the reported] performance was achieved with the first attempt at a fabrication run.”

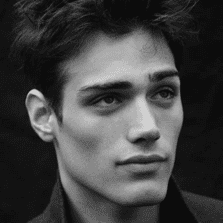

This view of the quantum light detector shows photodiodes and amplifier electronics on the chip. (Source: University of Bristol/QuPIQ)

Integrating PICs

Silicon photonics is swiftly emerging as a practical chip platform to develop quantum technologies, but connecting photonics with discrete electronics has limited device scalability and performance. Matthews and colleagues from QET Labs and the French National Center for Scientific Research (CNRS) broke new ground back in 2021 when they fabricated a fast homodyne detector by interfacing CMOS-compatible silicon nanophotonics with silicon germanium integrated electronics using imec (Leuven, Belgium) foundry services. Homodyne detection is used in quantum optics to measure optical fields. As the researchers wrote in Nature Photonics when reporting the development, the silicon PIC architecture “provides fast, multipurpose, homodyne detectors … and opens the way to full-stack integration of photonic quantum devices.”

Fast forward to today, and the team has “now used electronic-photonic integration, which is a big leap since our results in 2021,” Matthews said. “One of the key drivers for this monolithic integration has been the need to have miniaturized, faster transceivers for classical communications [in data centers, for example], so we’ve kind of piggy-backed on that.”

Matthews recalled that the team had been working to create a detector sensitive enough to measure quantum noise that could then be used to help generate quantum states of light. However, in the 2021 silicon photonic-based detector, the parasitic capacitances that accompanied the electronic interconnects between chips had introduced noise at higher speeds.

“Homodyne detection for quantum optics has been around for a long time … and while devices can be highly efficient and are used in all sorts of awesome measurements, the vast majority have been implemented with discrete photodiodes and discrete electronics, which [leads to] parasitic capacitance,” he said. “We realized monolithic integration could be the answer to this, and were one of the first groups to go, ‘Hang on a minute’—you can use integrated electronics with photonics for quantum homodyne detection.’”

With monolithic integration on their minds, Matthews and colleagues set to designing their quantum-noise-limited monolithic chip in-house at Bristol and then outsourced fabrication to Germany’s Leibniz Institute for High Performance Microelectronics (IHP), which offers various pilot lines for chip prototyping. They selected IHP’s 250-nm lithography BiCMOS process, which features a 250-µm silicon node, germanium-based photodiodes and vertically integrated heterojunction bipolar transistors, Critically, the process was offered as part of a multi-wafer project (MWP) service.

In MWP services, mask and wafer resources are shared so that different chip designs can be aggregated onto the same wafer to cut the costs of prototyping, reduce the number of design cycles, ease manufacturing at larger scales and ultimately reduce the entry costs for PIC developers. Such services are already offered by myriad industry players, including imec, LioniX International (Enschede, Netherlands), Smart Photonics (Eindhoven, Netherlands) and, of course, IHP.

Matthews described these services as “game changing” for photonics research and development, as they provide a relatively affordable alternative to more expensive foundry manufacturing. “When it comes to integrated quantum photonics, we’ve already seen the impact of multi-project wafer services for both silicon [photonics] and silicon nitride photonics,” he said. “Going forward, it would be even more powerful if we could have these services for other materials, such as thin-film lithium niobate.”

Costs and MWP services aside, it’s still early days for the researchers’ monolithic fabrication process, and Matthews couldn’t yet comment on chip yields. But as he put it, “As part of the fabrication process, we didn’t have to carry out lots and lots of trials with lots of different fabrication steps. Our first try worked, and that’s pretty awesome.”

Future work will target “more iterations, and we will be further improving the signal-to-noise ratio of our detector,” he added. “But it is already sensitive enough to make quantum measurements, such as the squeezing states of light.”

The researchers are also looking to raise the quantum efficiency of their integrated homodyne light detector. Right now, the on-chip efficiency for quantum experiments comes in at 29%, whereas that of their 2021 silicon photonics-based chip was 84%. “We would like to match this [figure of 84%], if not surpass it, and this will need further effort and research into the integrated photodiode efficiency,” Matthews acknowledged.

Still, with the latest results published in Science Advances2 and the promise of manufacturing PICs at scale via CMOS processes, the Bristol team’s new quantum light detector on silicon is a significant step toward high-speed quantum communications and computing.

“This is an interesting time for quantum technologies, and we need to keep working on the blue-sky research and low-TRL development. We need new ideas to fuel the next quantum technologies,” Matthews said. “But for quantum technologies to have a real impact, we also need to consider how we implement the technology at scale—we need to keep working on scalability wherever we can—and this is one of the reasons we pursued electronic-photonic integration in silicon.

“We’re already starting to see scalable and manufacturable photonics components in [early] quantum-photonics devices, such as sensors and communications systems,” he added. “I’m excited to see these developments happening very quickly.”